In the dynamic world of manufacturing, CNC manufacturing processes stand out for their precision, speed, and flexibility. Custom fabricators, particularly those with a focus on CNC services, are continuously evolving to meet the demands of industries ranging from aerospace to consumer goods. This evolution involves strategic enhancements in various stages of production, from design to post-processing. This post will explore how custom fabricators, including prominent CNC companies and custom fabricators in Alabama, streamline these processes to deliver superior products and services.

Optimized Design and Engineering

The journey to streamlined CNC manufacturing begins with optimized design and engineering. Custom fabricators leverage advanced CAD/CAM software to transform initial concepts into detailed, executable designs. This initial phase is crucial as it sets the groundwork for the entire manufacturing process. By optimizing designs early on, CNC companies ensure that the manufacturing phase is as efficient as possible, minimizing material waste and reducing production time. This approach not only enhances the manufacturability of the product but also significantly improves its functionality and performance.

Expertise in Material Selection

Choosing the right material is paramount in CNC manufacturing, and custom fabricators excel in this area. Their deep knowledge of material properties—such as strength, heat resistance, and weight—enables them to advise clients on the best choices for their specific applications. For instance, custom fabricators in Alabama may recommend aluminum for components that require lightweight and corrosion resistance or stainless steel for parts demanding high strength and durability. The expertise of these fabricators in material selection helps in reducing costs and enhancing the overall quality of the final product.

Integrated Project Management

Effective project management is the backbone of any successful manufacturing operation. Custom fabricators utilize integrated project management systems to ensure that every phase of the CNC process, from design to delivery, is executed flawlessly. These systems provide real-time visibility into the production timeline, enabling project managers to make informed decisions and adjustments on the fly. This proactive approach minimizes downtime and ensures that projects are completed on time and within budget, ultimately leading to higher client satisfaction.

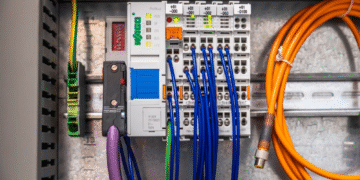

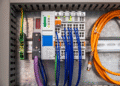

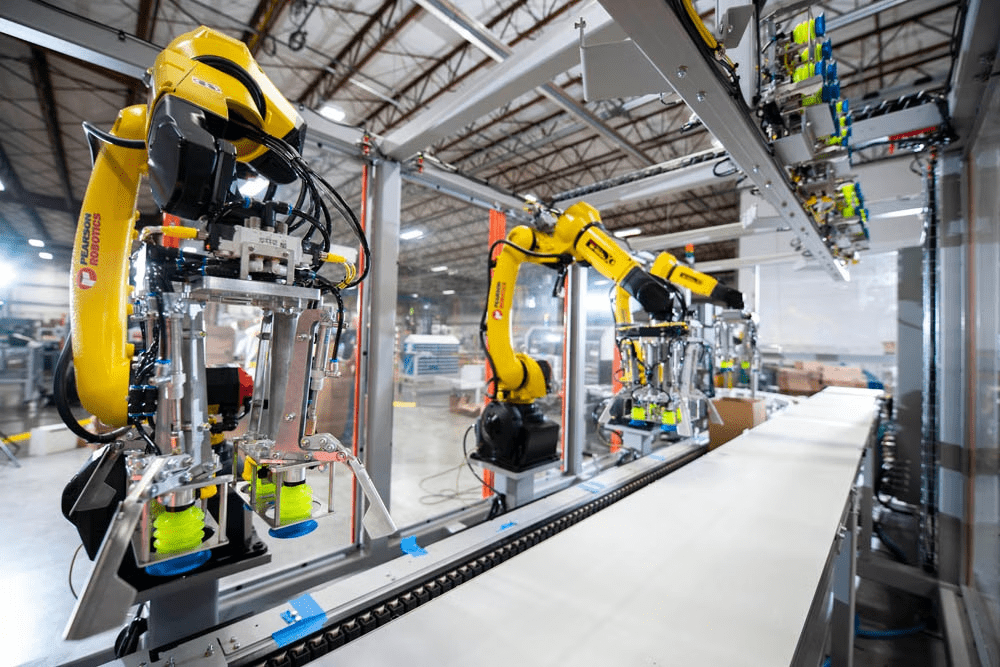

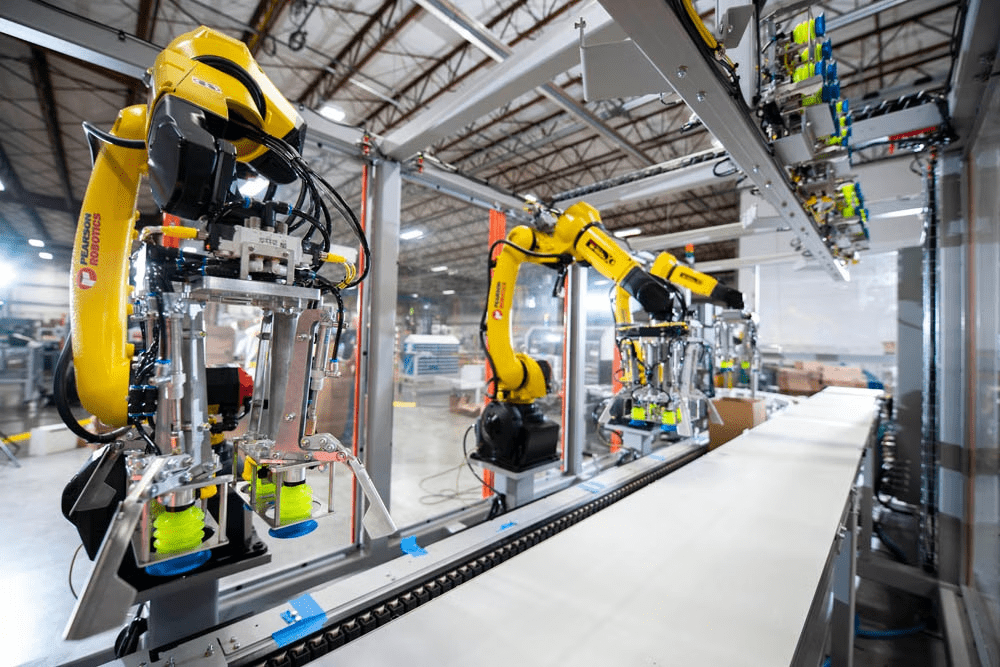

Automated CNC Programming

Automation plays a crucial role in the efficiency of CNC manufacturing. Custom fabricators employ sophisticated software to automatically generate CNC programming from digital designs. This automation significantly reduces the possibility of human error and speeds up the production process. For CNC companies, automated programming means that machines can operate virtually uninterrupted, increasing throughput and allowing for the rapid production of parts with consistent quality.

Quality Control and Inspection

Maintaining high quality is non-negotiable in CNC manufacturing. Custom fabricators implement rigorous quality control and inspection protocols to ensure that every part meets strict standards. Advanced measuring and testing equipment are used to detect any discrepancies in the parts produced, allowing for immediate corrections. This meticulous approach to quality control not only assures compliance with industry standards but also builds trust and reliability among clients seeking top-tier manufacturing solutions.

Post-Processing Capabilities

The final touch in the CNC manufacturing process involves various post-processing techniques such as painting, anodizing, or heat treating, which enhance the appearance and functionality of the parts. Custom fabricators offer a wide range of post-processing services, making them a one-stop shop for clients who require ready-to-use components. This capability not only simplifies the supply chain but also allows for greater customization, meeting the unique needs of each project.

Conclusion

Custom fabricators are at the forefront of revolutionizing CNC manufacturing processes. These fabricators ensure the delivery of high-quality, precision-engineered parts through optimized design and engineering, expertise in material selection, integrated project management, automated CNC programming, stringent quality control, and comprehensive post-processing capabilities. As the demand for more complex and high-performance parts grows, the role of custom fabricators, especially CNC companies and those based in regions like Alabama, becomes increasingly critical in the global manufacturing landscape.