Key Takeaways:

- Advanced manufacturing services are crucial for the resilience and operational readiness of the defense industry.

- Technologies such as additive manufacturing, robotics, and AI contribute to rapid prototyping, customized solutions, and efficient production.

- Improved supply chain management and predictive maintenance enhance the reliability and robustness of defense operations.

- Advanced manufacturing supports sustainability, safety, and compliance with stringent defense standards.

Introduction

By its very nature, the defense industry always demands resilience and operational readiness. The sector is increasingly adopting advanced manufacturing services to meet these stringent requirements. These technologies are pivotal in ensuring that defense operations remain robust, efficient, and capable of responding to ever-evolving challenges.

From additive manufacturing to robotics, the integration of advanced production techniques enhances operational efficiency and contributes to the overall agility and flexibility of defense operations. This article delves into the myriad ways advanced manufacturing services bolster the defense sector’s resilience, ensuring it can meet the high demands of modern warfare and defense strategies.

Additive Manufacturing for Rapid Prototyping

Additive manufacturing, commonly known as 3D printing, has revolutionized the design and production process within the defense industry. This technology allows for rapid prototyping, quickly producing complex and customized components without the need for extensive tooling or setup. Visit this website for detailed insights into the impact of advanced manufacturing on various sectors.

Producing prototypes swiftly enables defense contractors to test and iterate their designs more efficiently. This accelerates the development cycle and allows for immediate refinements based on real-world testing and feedback. Consequently, defense systems can be deployed faster, with higher reliability and performance.

Moreover, additive manufacturing supports the on-demand production of spare parts and critical components, reducing reliance on extensive inventory and lengthy supply chains. This capability is particularly beneficial in remote or conflict zones, where timely access to spare parts can be challenging. By leveraging additive manufacturing, defense forces can maintain operational readiness and sustain their equipment effectively, ensuring mission success.

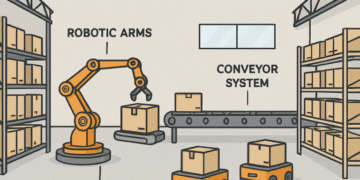

Robotics and Automation in Production

Robotics and automation are transforming manufacturing by enhancing precision, productivity, and safety. In the defense industry, these technologies are instrumental in streamlining production processes, reducing human error, and improving overall quality.

Automated robotic systems can perform repetitive and labor-intensive tasks with unmatched accuracy and speed. This increases production efficiency and frees human operators to focus on more complex and high-value activities. For instance, robots can assemble intricate components, ensuring consistent quality and reducing the risk of defects. Automated welding and machining processes enhance precision, ensuring critical defense equipment meets exacting standards.

Additionally, robotics plays a crucial role in enhancing workplace safety. Robots minimize the risk of accidents and injuries by taking over hazardous tasks, such as handling dangerous materials or operating in extreme environments. This protects workers and ensures compliance with stringent safety regulations, further reinforcing the resilience of defense manufacturing operations.