Factory performance rarely drops because of one large failure; it usually slips due to small integration gaps that compound over time. PLC-controlled systems depend on precise coordination between logic, hardware, and data flow to keep production moving. Identifying where those connections break down explains why some lines run smoothly while others struggle to meet output goals.

Uncoordinated Signals Causing Machine Idle Time

Uncoordinated signals occur when PLC logic sends commands without confirming downstream readiness. A conveyor may wait on a machine that already finished its cycle, or a robot may pause because it never received a clear handoff signal. These micro-pauses add up, creating idle time that operators often mistake for mechanical delays.

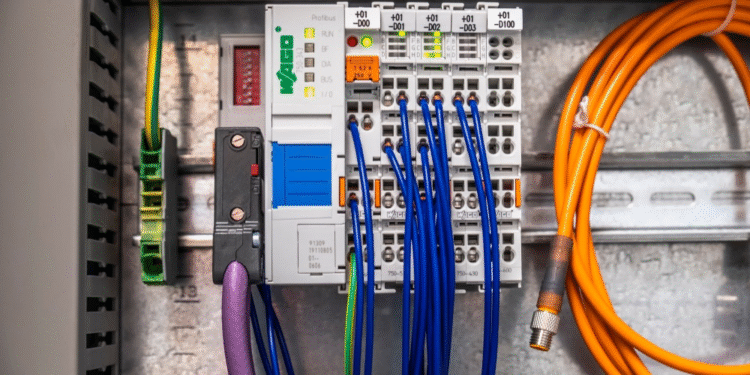

Better signal coordination starts with reviewing how devices communicate rather than adding speed. A PLC system integrator can restructure logic so machines acknowledge each other’s states before actions occur. This alignment reduces unnecessary waiting and keeps equipment moving in sync.

Missing Feedback Loops Slowing Cycle Rates

Feedback loops confirm that actions actually happened, not just that commands were sent. Without them, PLCs rely on timers instead of real conditions. Timers must be conservative to avoid faults, which stretches cycle times beyond what equipment truly needs. Proper PLC programming replaces guesswork with verification. Sensors confirm positions, speeds, and completions so the system advances immediately once conditions are met. This approach tightens cycles while maintaining safety and consistency.

Mismatched Tag Names Creating Logic Confusion

Tag naming inconsistencies cause confusion across programs, HMIs, and documentation. One signal might be labeled differently in each place, forcing technicians to cross-reference constantly. During troubleshooting, that delay increases downtime and frustration. A custom PLC structure uses consistent naming conventions that reflect function and location. Clear tags improve readability and reduce errors during edits. PLC programming companies often uncover significant efficiency losses simply by standardizing tag systems.

Outdated Firmware Blocking Newer Device Links

Firmware mismatches prevent PLCs from communicating with newer drives, sensors, or network devices. Even if hardware is physically compatible, outdated firmware can block data exchange or limit features. This creates partial integrations that never perform as intended.

Updating firmware allows PLCs to use modern protocols and diagnostics. A PLC system integrator evaluates firmware compatibility before blaming hardware. These updates often unlock performance gains without replacing existing controllers.

Poor Timing Between Sensors and Actuator Responses

Timing gaps between sensor input and actuator response create inconsistent behavior. A sensor may trigger correctly, but delayed logic processing causes late actuator movement. The result can be misalignment, jams, or repeated corrections.

Optimized PLC programming reduces scan delays and prioritizes critical signals. Adjusting task order and interrupt handling improves responsiveness. These refinements help machines react smoothly instead of lagging behind real-world conditions.

Incomplete Error Handling That Halts Production Runs

Some PLC programs treat minor issues the same as major faults. A brief sensor glitch can stop an entire line because the logic lacks graduated responses. Operators then reset systems repeatedly without understanding root causes.

Advanced error handling categorizes faults by severity. Custom PLC logic can allow controlled pauses, retries, or bypasses while alerting staff appropriately. This keeps production running safely instead of stopping for every minor anomaly.

Patchwork Code That Grows Harder to Maintain

Patchwork code forms when quick fixes are layered over old logic without cleanup. Over time, routines duplicate functions, conditions contradict each other, and changes ripple unpredictably. Maintenance teams hesitate to modify code because outcomes are uncertain.

Refactoring PLC programs restores structure and intent. A PLC programming company reorganizes logic into clear modules with defined purposes. Clean code reduces future downtime and simplifies expansions.

Ignored Interlocks Letting Faults Ripple Through Systems

Interlocks protect equipment by preventing actions under unsafe conditions. When they are missing or improperly implemented, faults spread from one machine to another. A single issue can cascade into a line-wide stoppage.

Well-designed interlocks isolate problems instead of amplifying them. PLC programming that respects equipment dependencies keeps faults contained. This containment protects assets and shortens recovery time.

Data Points Left Untracked That Hide Process Bottlenecks

Many PLC systems collect minimal data beyond basic operation. Without tracking cycle times, wait states, or fault frequency, bottlenecks remain invisible. Teams respond to symptoms instead of addressing root causes.

Expanding data collection within PLC logic reveals where time is lost. Custom PLC configurations log key metrics that support informed decisions. Visibility into process behavior turns assumptions into measurable improvements.

If integration gaps are limiting system performance, RL Consulting can help identify and correct them. Their work focuses on aligning PLC logic, hardware communication, and data flow to improve efficiency. Structured PLC programming support helps production systems operate with clarity, consistency, and room to grow.