Key Takeaways

- Ergonomic casters significantly improve workplace safety by reducing strain and injuries.

- Choosing the correct caster enhances efficiency and productivity by facilitating smoother movement of heavy equipment.

- Innovative caster designs contribute to sustainability efforts by providing durable and recyclable options.

Boosting Workplace Safety with Ergonomic Casters

In the fast-paced world of manufacturing, ensuring the safety of workers is not just a priority but a necessity. One solution to reducing workplace injuries is the implementation of ergonomic casters. These devices are crafted to minimize the physical stress on workers by providing smoother and more manageable heavy equipment movements. By integrating ergonomic casters, businesses can significantly reduce the risk of musculoskeletal injuries commonly associated with lifting and shifting hefty loads. This proactive approach not only secures the physical well-being of employees but also reinforces a company’s commitment to health standards, which can, in turn, reduce absenteeism related to injuries and improve overall workforce morale. Among the various ergonomic casters, swivel casters with lock stand out for their added functionality. These casters provide mobility and can be locked in place, offering stability when needed. Such features are instrumental in safeguarding workers from accidents, contributing to a safer working environment overall. These casters prevent unnecessary shifts and potential mishaps by enabling equipment to be fixed securely during critical operations, thereby supporting a safe and well-organized workplace environment.

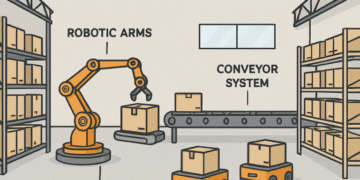

Enhancing Productivity through Smooth Operations

Optimizing every part of the manufacturing process is crucial in industries where time equals money. Casters play a pivotal role here by enabling seamless equipment and raw materials movement across the factory floor. This smooth operation is critical in maintaining the flow of work and increasing output. Enhancing efficiency can lead to faster production times and cost savings, which are vital for any manufacturing business. With these improvements, businesses can better meet deadlines, minimize production downtime, and ultimately increase their competitive edge in the market.

Understanding Different Types of Casters

The array of caster types available can be overwhelming, but understanding their distinct features is essential. Swivel casters enable equipment to move in all directions, making them ideal for tight navigation environments. On the other hand, rigid casters allow movement in a straight line, which is perfect for longer distances without the need to maneuver. Selecting the correct type tailored to your workspace needs can make all the difference in operational efficiency. Swivel casters with locks, for example, provide the versatility of 360-degree movement combined with the security of immobilization when necessary, proving invaluable in dynamic work environments where both movement and stability are required.

Innovative Designs for Sustainability

With growing environmental concerns, sustainability in manufacturing is a hot topic. Modern caster designs are increasingly focusing on sustainable materials and longevity. Many are now made from recycled materials, ensuring they are durable and eco-friendly. Such sustainable manufacturing practices may align with regulatory requirements and enhance a company’s brand reputation as a responsible entity. The EPA’s sustainability practices detail how these approaches can positively impact the environment. By reducing waste and minimizing environmental footprints, these practices help manufacturers conserve resources and promote a greener future, which is becoming an increasingly important consideration for consumers and regulatory bodies.

Essential Considerations When Selecting Casters

Choosing the right casters involves evaluating various factors, including load capacity, wheel material, and the type of flooring. These elements will influence how well the casters perform and their longevity. Consulting with a professional or conducting a thorough analysis can ensure that the casters meet all operational demands and user needs. For instance, heavy-duty casters are essential for equipment with substantial weight, while softer wheel materials may be necessary for more delicate flooring surfaces to prevent damage and wear. Manufacturers can achieve functional and economic benefits by aligning caster characteristics with specific operational requirements.

Maintenance Tips for Prolonging Caster Life

Regular maintenance can significantly enhance the lifespan and functionality of casters. Keeping wheels clean from dirt and debris, checking for wear and tear, and ensuring they are properly aligned can prevent performance issues. Maintenance not only prevents premature replacements but also maintains the safety standards of the workplace. Establishing a routine maintenance schedule that includes inspections and prompt rectification of detected issues is key to sustaining optimal performance. Additionally, lubricant application on moving parts can reduce friction and enhance movement efficiency, further extending the life of the casters.