Key Takeaways

- Efficient material handling drives productivity, cost savings, and operational scalability.

- Automation and robotics (AMRs, AGVs) increase speed and accuracy while reducing human error.

- AI and machine learning optimize workflows, route planning, and predictive maintenance.

- IoT integration provides real-time monitoring, transparency, and proactive decision-making.

- Sustainable practices, such as electric forklifts and energy-efficient layouts, reduce emissions and costs.

- Advanced conveyors and autonomous forklifts/tuggers improve throughput, safety, and adaptability.

- Tools such as sludge dewatering equipment rental support specialized operational needs.

Efficiency in material handling has become a fundamental driver of operational success for businesses ranging from retail to manufacturing. Through innovations blending automation, smart technology, and sustainable practices, organizations can transform how they move and manage goods across their facilities. Selecting the right solutions, such as sludge dewatering equipment rental, streamlines logistics, saves costs, and boosts productivity, enabling seamless scaling as business grows.

Today’s advanced techniques help organizations adapt to shifting layouts and fluctuating demand while maintaining high service standards. With new technologies, companies can optimize the flow of products from receipt to shipping, integrate intelligent systems for real-time decision-making, and minimize the bottlenecks that slow down warehouses or shop floors. As businesses look to the future, investing in these innovations ensures they remain resilient and competitive in an evolving marketplace.

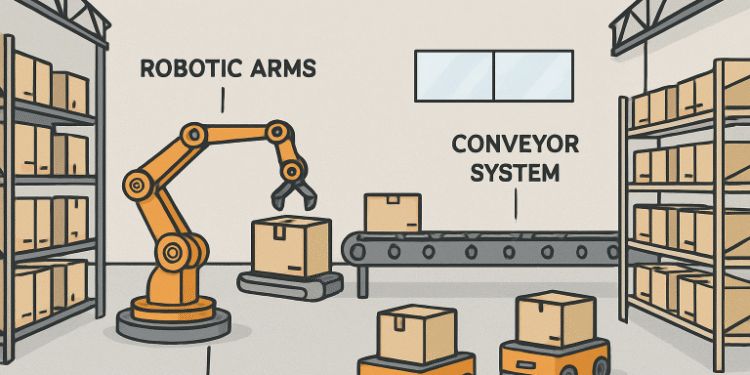

Automation and Robotics Integration

Adopting automation and robotics in material handling opens new levels of speed and consistency. Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) can transport goods in complex environments, minimizing human error and freeing staff for higher-value tasks. These robots rely on sensors and artificial intelligence for safe navigation, adapting in real time to dynamic layouts and operational changes. By implementing these automated solutions, facilities can operate more efficiently and respond quickly to peak demands or unexpected shifts in production lines.

AI and Machine Learning Applications

Artificial Intelligence (AI) and Machine Learning (ML) have gone beyond automation to optimize key decision points within material handling operations. These systems sift through large data volumes to identify patterns that would otherwise go unnoticed. Organizations can anticipate maintenance needs, proactively plan for demand spikes, and ensure optimal resource allocation. Machine learning algorithms further enhance processes like order picking by computing the fastest possible routes, thereby reducing travel time and improving overall throughput.

Internet of Things (IoT) Integration

By connecting sensors and equipment, the Internet of Things (IoT) delivers actionable insights across warehouses and factories. IoT technology automatically monitors inventory levels, tracks machine condition, and oversees environmental conditions, including temperature and humidity. Managers benefit from access to real-time data that reveals inefficiencies and identifies when intervention is needed. Improved connectivity and transparency enabled by IoT are helping organizations reduce errors, optimize workflows, and maintain higher levels of safety and compliance.

Sustainable Material Handling Practices

Organizations are increasingly adopting initiatives to minimize the environmental footprint of their material handling operations. Switching to electric forklifts or investing in recyclable containers reduces emissions and waste in daily workflows. Warehouse layouts designed for energy efficiency can yield further savings by leveraging natural lighting, improved insulation, and energy-smart equipment. As more businesses aim to align with global sustainability goals, adopting eco-friendly approaches not only benefits the planet but also reduces operational costs and enhances company reputation within the supply chain.

Advanced Conveyor Systems

Modern conveyor solutions offer far more than traditional belt conveyors. Today’s systems feature magnetic motor-driven rollers, which can be configured for high-speed transport and precise placement without the need for extensive mechanical adjustments. These modular systems handle a wide variety of products, supporting businesses that frequently change their product mix or warehouse layouts. Upgraded conveyors also use less energy and require minimal maintenance, which helps facilities maximize uptime and achieve a faster return on investment.

Autonomous Forklifts and Tuggers

The evolution of autonomous forklifts and tuggers is a game-changer for internal logistics. These vehicles rely on AI-driven perception and navigation to safely navigate crowded, ever-changing warehouse environments. Autonomous vehicles excel at repetitive, physically intensive tasks, reducing strain on human workers while maintaining safe, consistent performance. Facilities that implement these solutions typically experience fewer workplace incidents and significant improvements in material flow accuracy and speed.

Final Thoughts

Modern material handling strategies combine emerging technologies with sustainability, positioning organizations to thrive amid growing operational challenges. Integration of automation, AI, IoT, and energy-efficient designs ensures businesses can streamline material flows, reduce costs, and meet evolving customer demands. By adopting these innovative solutions, companies build a robust foundation for continuous improvement and future readiness.